USP NF Sterile Compounding

USP NF 795/797/800/503B sterile compounding, pharmaceutical cleanrooms per USP NF, FDA, and Florida Board of Pharmacy 797 standards. Engineered to ISO 14644-1 cleanroom classifications. Multi-zones maintained at ISO Class 7(30 ACPH, +.02 WC), and ISO Class 8(20 ACPH, +.02 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H., .02 WC. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Pharmaceutical Cytotoxic Processing

FDA pharmaceutical aseptic processing cleanrooms per FDA, and CGMP. Engineered to ISO 14644-1 cleanroom classifications. Multi-zones maintained at ISO Class 5(350 ACPH, +.04 WC), ISO Class 7(60 ACPH, +.02 WC), ISO Class 7(60 ACPH, -.02 WC) and ISO Class 8(20 ACPH, +.02 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Regenerative Tissue Engineering

FDA, CGMP, CGTP, grade cleanrooms for the manufacture and processing of human cell, tissue, and cellular and tissue-based products (HCT/Ps). Multi-zone cleanrooms maintained at ISO Class 5(350 ACPH, +.04 WC), ISO Class 7(60 ACPH, +.02 WC), and ISO Class 8(20 ACPH, +.02 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H., .04 WC. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Hematopoietic Stem Cell Laboratory

Cell processing laboratory (CPL) to support new hematopoietic stem cell transplant programs per FDA, CGMP, ISSCR. Engineered to ISO 14644-1. Multi-zone cleanrooms maintained at ISO Class 5(350 ACPH, +.04 WC), ISO Class 7(60 ACPH, +.02 WC), and ISO Class 8(20 ACPH, +.02 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H., .04 WC. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Radiopharmaceutical PET Manufacturing

Radiopharmaceutical PET manufacturing facilities for the efficient commercialization of radiopharmaceutical products per USP NF, FDA, and NRC standards. Engineered to ISO 14644-1 cleanroom classifications. Multi-zones maintained at ISO Class 7(30 ACPH, +.02 WC), and ISO Class 8(20 ACPH, +.02 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Surgical Larval Therapy

Surgical debarment therapy cleanroom incubation facility for the implementation of cost effective debarment treatment for wound care therapies per FDA, CGMP. Engineered to ISO 14644-1 cleanroom classifications. Single-zone cleanroom maintained at ISO Class 7(60 ACPH, +.04 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H., .04 WC. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Hospital Satellite Pharmacy

USP NF 797/800 hospital satellite pharmacy for the sterile compounding and processing of chemotherapy medications and solutions. Engineered to ISO 14644-1 cleanroom classifications. Multi-zone cleanrooms maintained at ISO Class 7(30 ACPH, +.02 WC), and ISO Class 8(20 ACPH, +.02 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Hospital USP Pharmacy

USP-797 hospital pharmacy for the sterile compounding of pharmaceutical medications and solutions per hospital specifications. Engineered to ISO 14644-1 cleanroom classifications. Multi-zone cleanrooms maintained at ISO Class 7(30 ACPH, +.02 WC), and ISO Class 8(20 ACPH, +.02 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Hospital Cancer Research Labs

Hospital cancer research laboratories and cryogenic freezer storage rooms per FDA, ISO 14644-1, AHSP, and Florida AHCA standards. Engineered to ISO 14644-1 cleanroom classifications. Multi-zone cleanrooms maintained at ISO Class 7(60 ACPH, +.04 WC), and ISO Class 8(20 ACPH, +.04 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

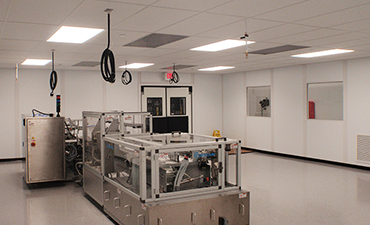

Pharmaceutical Contract Packaging

Pharmaceutical and cosmetic contract packaging cleanroom for ISO grade filling and packaging of pharmaceutical and cosmetic products per FDA. Engineered to ISO 14644-1. Multi-zones maintained at ISO Class 7(60 ACPH, +.04 WC), and ISO Class 8(20 ACPH, +.04 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Monitored continuously.

Pharmaceutical Contract Packaging

Pharmaceutical contract packaging cleanroom for ISO grade filling and packaging of pharmaceutical and cosmetic products per FDA. Engineered to ISO 14644-1 cleanroom classifications. Multi-zone cleanrooms maintained at ISO Class 7(60 ACPH, +.04 WC), and ISO Class 8(20 ACPH, +.04 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Transdermal Drug Delivery

Transdermal drug delivery cleanroom to ISO 14644-1 and FDA guidelines for Transdermal drug delivery patches and related pharmaceuticals. Engineered to ISO 14644-1 cleanroom classifications. Multi-zone cleanrooms maintained at ISO Class 7(60 ACPH, +.04 WC), and ISO Class 8(20 ACPH, +.04 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Medical Device Manufacturing

Medical device manufacturing cleanroom to ISO 14644-1 and FDA guidelines for medical device manufacturing and assembly processes. Engineered to ISO 14644-1 cleanroom classifications. Multi-zone cleanrooms maintained at ISO Class 7(60 ACPH, +.04 WC), and ISO Class 8(20 ACPH, +.04 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Medical Device Manufacturing

Medical device manufacturing ISO class multi shift changeroom designed to ISO 14644-1 for 18 technicians timed entry and egress. Engineered to ISO 14644-1 cleanroom classifications. Multi-zone cleanrooms maintained at ISO Class 7(60 ACPH, +.04 WC), and ISO Class 8(20 ACPH, +.04 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Medical Device Manufacturing

Medical device manufacturing cleanroom designed to ISO 14644-1, CGMP, and current CFR 21 standards for processing and packaging. Engineered to ISO 14644-1 cleanroom classifications. Multi-zone cleanrooms maintained at ISO Class 7(60 ACPH, +.04 WC), and ISO Class 8(20 ACPH, +.04 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Micro Electronics Manufacturing

Micro electronics cleanroom designed to ISO 14644-1 cleanroom classifications, ASTM, standards for processing and packaging of electronic components. Engineered to ISO 14644-1 cleanroom classifications., Multi-zones maintained at ISO Class 7(60 ACPH, +.04 WC), and ISO Class 8(20 ACPH, +.04 WC). Controlled to 68°F ± 5°F, 35% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Micro Electronics Laboratory

Micro electronics cleanroom laboratory for the testing and assembly of micro electronics components per ISO 14644-1 and ASTM standards. Engineered to ISO 14644-1 cleanroom classifications. Multi-zone cleanrooms maintained at ISO Class 7(60 ACPH, +.04 WC), and ISO Class 8(20 ACPH, +.04 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Micro Electronics Laboratory

Micro electronics laboratory for the testing and assembly of micro electronics components per ISO 14644-1 and ASTM E2217-12 standards. Engineered to ISO 14644-1 cleanroom classifications. Multi-zone cleanrooms maintained at ISO Class 7(60 ACPH, +.04 WC), and ISO Class 8(20 ACPH, +.04 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Architectural Glass Laminating

Architectural glass laminating with PVB interlayer per ISO 14644-1 with temperature and relative humidity controls for application and storage of PVB. Engineered to ISO 14644-1 cleanroom classifications. Multi-zone cleanrooms maintained at ISO Class 7(60 ACPH, +.04 WC), and ISO Class 8(20 ACPH, +.04 WC). Controlled to 68°F ± 5°F, 35% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Aerospace Testing and Assembly

Micro electronics cleanrooms for the testing and assembly of aerospace components per ISO 14644-1 and ASTM E2217-12 standards. Engineered to ISO 14644-1 cleanroom classifications. Multi-zone cleanrooms maintained at ISO Class 7(60 ACPH, +.04 WC), and ISO Class 8(20 ACPH, +.04 WC). Controlled to 68°F ± 5°F, 35% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.

Aerospace Testing and Assembly

Aerospace components cleanrooms for the testing and assembly of aerospace components per ISO 14644-1 and ASTM E2217-12 standards. Engineered to ISO 14644-1 cleanroom classifications. Multi-zone cleanrooms maintained at ISO Class 7(60 ACPH, +.04 WC), and ISO Class 8(20 ACPH, +.04 WC). Controlled to 68°F ± 5°F, 55% R.H. ± 5% R.H. Cascading pressurization maintaining differential pressures between cleanroom zones. Continuous monitoring.